Medical operations depend much on metal components as they ensure accuracy, durability, and safety. For surgical instruments such as scalpels, forceps, and scissors—where even a little mistake may affect a patient's life—precision is quite vital. Metals like titanium and stainless steel let these tools be created by the top Medical Metal Parts Manufacturers with great precision and sharp edges.

The durability ensures that implants—such as hip or knee replacements—may last years of usage without breaking or corroding. Safety comes from the biocompatibility of metals such as titanium, which the human body absorbs without damage. These attributes taken together enable surgeons to confidently carry out difficult operations, enabling patients to recuperate more quickly and lead better lives.

Key Properties of Metals for Medical Applications

The special qualities of metals used for medical purposes make them perfect for usage in hospitals. The most crucial among them is biocompatibility. This indicates that the metal does not induce reactions and is safe for the human body. Tools, implants, and other devices are strong and durable enough to survive a long period even under high pressure.

Titanium and stainless steel have an exemplary corrosion resistance. These metals do not rust or break down when come across physiological fluids. Malleability is another important quality as it lets metals be molded into exact instruments and implants. Finally, metals such as platinum and gold provide conductivity, which is essential for pacemakers. In medical treatment and operations, these special qualities make metals dependable, safe, and necessary. As a result, all the leading Medical Metal Components Manufacturers in India use them the most.

Common Metals Used in the Medical and Healthcare Industry

Metals are crucial in healing and invention in the complex field of medical research; each one adds special qualities to ensure life-saving accuracy. Unmatched durability and corrosion resistance make stainless steel, a paragon of strength and resilience, fit surgical tools, implants, and other hospital equipment. Titanium is an amazing metal admired for its biocompatibility. It is light-weight but remarkably strong combining with the human body in hip replacements, dental implants, and bone plates.

With their glossy hardness, cobalt-chromium alloys are fit for joint replacements and provide strong under load for decades. Platinum and gold are used in devices that pump life into hearts. Their amazing conductivity ensures pacemaker and stent-perfect operation. Even aluminum, with its feather-light character, finds use in prostheses, providing movement and freedom. These metals used together create a tapestry of durability, strength, and accuracy that raises the standards of healthcare to incredible heights. This is why all the leading Medical Metal Parts Manufacturers opt for them as raw materials.

Applications of Metal Components in Medical Procedures

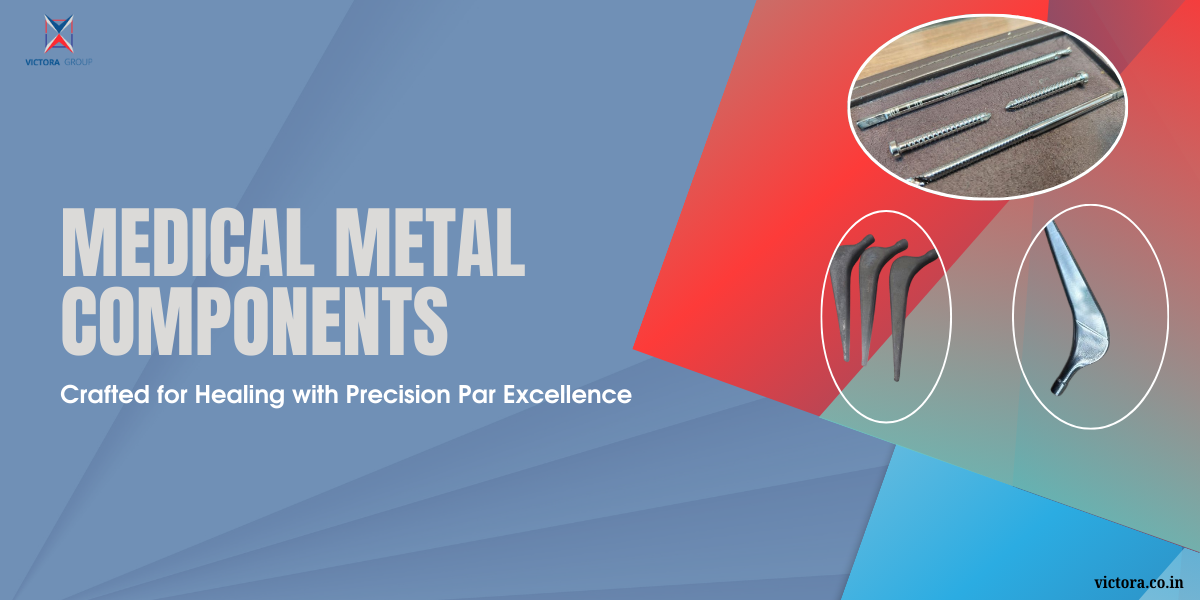

Modern medical treatments are based on metal components, which have unparalleled strength and accuracy, promoting innovation and healing like never before. Within the field of surgical instruments, shining scalpel blades, scissors, forceps, and retractors provide fine accuracy where every action balances life. Restoring strength and movement, orthopedic implants including hip and knee replacements, bone screws, and plates become an unseen companion within the human body.

Metals also help dentistry to create miracles; implants, braces, and crowns easily correct smiles and rebuild confidence. Pacemakers, stents, and prosthetic heart valves go well with the cardiovascular region, preserving the rhythm of life.

For individuals seeking mobility, metals form prostheses, wheelchairs, and walking aids, return freedom back to many lives. In diagnostics as much as in imaging instruments, MRI machines, and surgical robotics, metal's accuracy is remarkable. These tools used together ensure resilience, creativity, and optimism in the realm of human health.

Concluding Remarks

High-precision components supporting modern healthcare developments are produced by Medical Metal Parts Manufacturers. Using premium materials including stainless steel, titanium, and cobalt alloys, these manufacturers specialize in creating medical metal components including surgical instruments, implants, and diagnostic tools. Having expertise in Metal Components Tooling, they ensure that every product satisfies rigorous criteria of durability, precision, and safety needed in important medical operations.

With new technologies and procedures like Hydrogen Metal Components manufacturing, the efficiency and performance of medical equipment have gone to a new high. Thus, Medical Metal Components Manufacturers assist healthcare professionals in providing life-saving therapies by integrating modern tooling with precise engineering, transforming patient care with dependable and excellent metal components.

Also Read: Electric Mobility: Overview, Key Facts, Major Components, and Emerging Trends